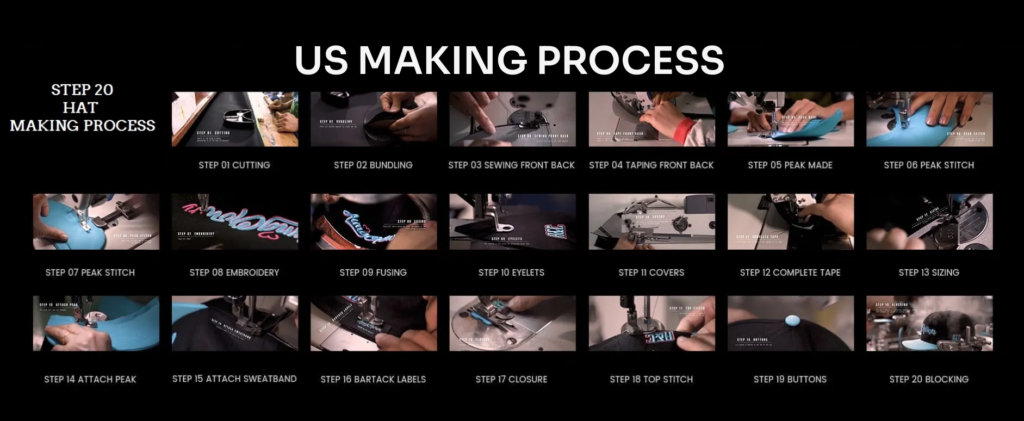

Let’s take a look at the steps involved in making a cap.

1. Cutting the Fabric

The first step in making a cap is choosing the fabric and cutting it into the right shapes. Different parts of the cap, like the crown (the top part) and the brim (the part that sticks out), are cut from fabric. The fabric used for caps can vary, but common options include cotton, polyester, or mesh, which are all durable and comfortable materials.

At Novae-Apparel, we carefully cut high-quality fabrics to ensure every cap looks great and lasts long.

2. Sewing the Panels Together

Once the fabric pieces are cut, the next step is to sew them together to form the shape of the cap. Most caps have six panels sewn together to create the rounded top. These panels are stitched with precision so the cap fits well and holds its shape.

We at Novae-Apparel use modern sewing machines to make sure every cap is stitched perfectly.

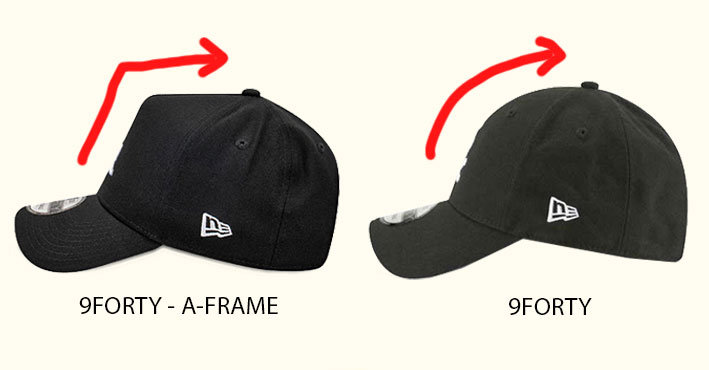

3. Adding the Brim

The brim, also called the visor, is the part of the cap that shields your eyes from the sun. It’s usually made from stiff material, often with a layer of fabric covering it. The brim is attached to the front of the cap with careful stitching to make sure it stays firm and in place.

Our brims at Novae-Apparel are designed to be durable and comfortable for all-day wear.

4. Attaching the Sweatband

A sweatband is sewn inside the cap to absorb moisture and keep sweat away from your face. This makes the cap more comfortable, especially during sports or outdoor activities. The sweatband is often made from soft, absorbent material that fits snugly around the head.

At Novae-Apparel, we use high-quality sweatbands that keep the wearer cool and dry.

5. Adding the Logo or Design

Now comes one of the most important steps—adding your logo or design to the cap. Logos can be embroidered or printed onto the fabric, depending on the style you want. The logo is usually placed on the front of the cap, but it can also be added to the sides or back.

At Novae-Apparel, we offer customizable logo options so that your cap perfectly represents your brand.

6. Final Assembly and Quality Check

Once all the parts are assembled, the cap goes through a final inspection. This step ensures that the cap is well-made, with no loose stitches or defects. We make sure that the cap fits well and looks exactly how it should before it’s ready to be shipped.

At Novae-Apparel, every cap goes through a strict quality check to ensure the best product reaches our customers.

Why Choose Novae-Apparel?

At Novae-Apparel, we are experts in cap production. Our factory in China has 23 production lines, and we can produce 1.26 million pieces per month. We serve large corporate buyers, brand owners, and distributors in markets like the USA, Europe, and Canada. We take pride in offering high-quality caps that are customizable with your logo.

We promote our products through exhibitions around the world to connect with businesses that need top-quality headwear products.

Conclusion

Making a cap involves many steps, from cutting the fabric and sewing the panels to adding the brim and sweatband. With attention to detail and high-quality materials, the result is a stylish and functional cap that can be worn for sports or casual use. At Novae-Apparel, we make sure that every cap is made with care and precision.

If you’re ready to create custom caps for your business, contact us at info@novae-apparel.com or visit our website at novae-apparel.com to learn more!